Projects

Wood Pellet Drying System

Location

Corinth, ME, USA

Product

Wood pellets composed of mixed wood species

Rate

20 tons/hour of dried wood product at 10% moisture content

Want to learn how PDI can help you?

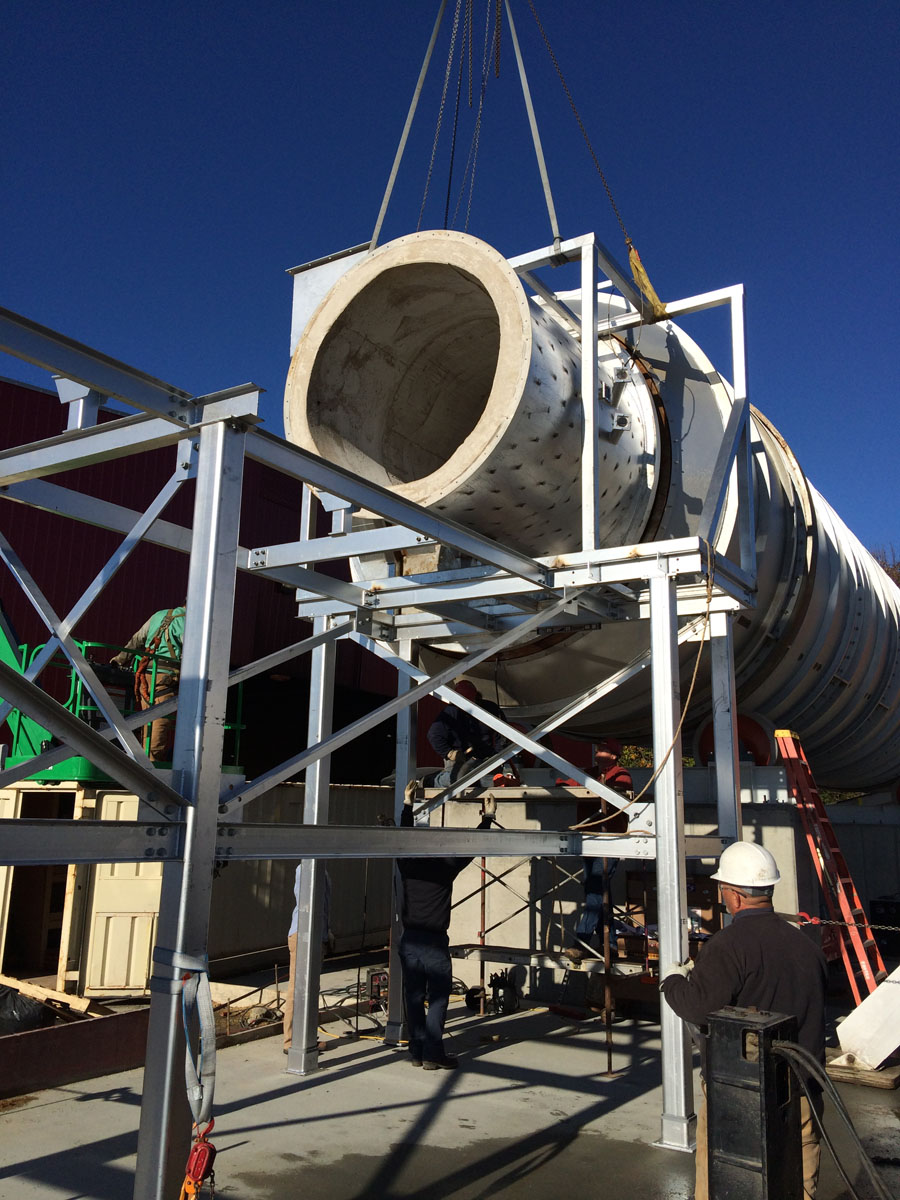

PDI was contracted to build a complete wood pellet drying system, including a multi-fuel burner, rotary drum dryer, and a discharge/recycle subsystem. This equipment was coupled to existing pelletizers and baggers to construct a complete pellet mill. For this contract, PDI delivered a wet fuel burner that can burn both white wood and green bark input, at a wide variety of input moisture contents. The dryer, in conjunction with the burner, can produce up to 20 tons/hour of dried material for the pelletizers. PDI also custom designed an air recycling system that conserves the heat that leaves the dryer, maximizing the energy efficiency of the plant.

This plant’s burner system operates primarily on wet fuels — white wood and green bark at about 50% moisture content. As is the case with many PDI burners, this burner’s fuel source is almost entirely waste wood, making the system as economical as possible. This particular burner produces 45 million BTU/hour of thermal energy from roughly 5 tons/hour of fuel. In addition, this burner was designed with custom PLC logic, which was integrated with the dryer and existing plant facilities to ensure smooth and automatic operation.

The PDI dryer installed for this plant is a 14X60 rotary drum dryer. It accepts just over 36 tons/hour of undried material at 45% moisture, from which it produces 20 tons/hour of dried wood product at 10% moisture content. This PDI system also incorporates an air-recycling cyclone, which recirculates hot air from the dryer outlet back through the inlet, making the process as energy efficient and economical as possible. For this project, PDI provided engineering services, aiding in plant design and assisting in smooth startup and initial product runs.